Employees at the Belmont warehouse are seeing significant improvements after implementing four robotics process automations (RPAs) between August 2020 and February 2021.

The RPA technology has eliminated the need for manual dual data entry by using a computer bot to copy data from one system into another.

RPA software replicates human behavior to perform routine, repeatable, rules-based tasks. It was implemented at Citizens Energy Group as a result of a prior strategic planning process.

“Emerging technologies like this can potentially add tremendous value for our stakeholders and customers by allowing us to operate more efficiently, make better data-driven decisions, and augment human interactions internally and externally,” said Joe Schriever, IT Manager of Business Relationships. “RPA is a great technology for Citizens because of its focus on eliminating time-consuming, redundant tasks and making processes leaner and more efficient.”

“Emerging technologies like this can potentially add tremendous value for our stakeholders and customers by allowing us to operate more efficiently, make better data-driven decisions, and augment human interactions internally and externally,” said Joe Schriever, IT Manager of Business Relationships. “RPA is a great technology for Citizens because of its focus on eliminating time-consuming, redundant tasks and making processes leaner and more efficient.”

Prior to implementing RPA, every transaction completed in Infor EAM had to be manually replicated in Oracle EBS. The former is used by wastewater maintenance employees to track expenses, and the latter is used by Supply Chain as the system of record for financial data.

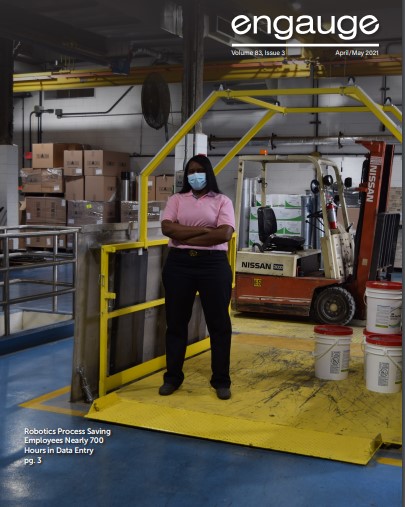

Latasha Stewart, Belmont Warehouse Supervisor, (pictured at right) said, “Before we started utilizing RPA, much of my time was spent ensuring both of our systems were in sync. This platform has eliminated the manual process of replicating data for approximately 9,260 transactions per year.”

The elimination of dual data entry between EAM and EBS is saving about 620 hours annually. In addition, the automation technology is eliminating dual data entry previously required for ordering inventory, which is saving another 65 hours per year.

“We are repurposing those saved hours to eliminate obsolete inventory, re-organize the warehouse to reduce travel times for retrieving high-turn stock items, and increase our self-service storage stocking for low-value common materials,” said Stewart.

This process also has reduced by half the chances of typical manual data-entry errors and the time needed for rework.

Meet the Team

In the spirit of One Company, One Culture, the following employees from IT, Wastewater Operations and Maintenance, and Supply Chain worked together to successfully implement the RPA project at the Belmont warehouse: Carla Baber, Stacy Caldwell, Bob Cammack, Susan Craven, Jared Garner, Tracye George, Tony Gomez, John Harz, Shawn Jackson, Gary Justus, Joe Schriever, Latasha Stewart, Vincent Stewart, Susan Unversaw

Interested in Implementing Robotic Process Automation (RPA)?

If you’re interested in discussing how RPA could be implemented in your area, contact Joe Schriever.

IT will set up a discovery call to learn more about the process you are interested in improving with RPA. If it appears to be a good candidate for the technology, the Quality Department will review and suggest possible ways to streamline the process. After that, the automation phase will begin with a detailed design document that will be used by the development team to create the bot. Before going live, the bot process will be tested and any defects will be resolved.

Brent Williams, Laborer, organizes inventory with a forklift; Nathan Summers, Technician, distributes supplies from the warehouse. Not pictured: Jarrett Helton, Technician